PAIRAN’s depolymerization technology can be used to produce third generation fuels from waste tyres and plastics generated from our day to days operation .

PAIRAN’S operations support distributed energy production, which is strategically important for India and strengthen energy self-sufficiency. PAIRAN also aid’s the progress of India’s carbon offset target. PAIRAN’s products can be utilized directly in industrial heat production replacing imported cokes or light and heavy liquid fuel oil. Emerging alongside of these applications is the use of this fuel to power diesel engines. In the near future, it will be possible to upgrade our into products comparable to normal transportation fuels. Interesting applications in the longer term are found in the chemical industry.

P A I R A N ‘ s T E C H N O L O G Y

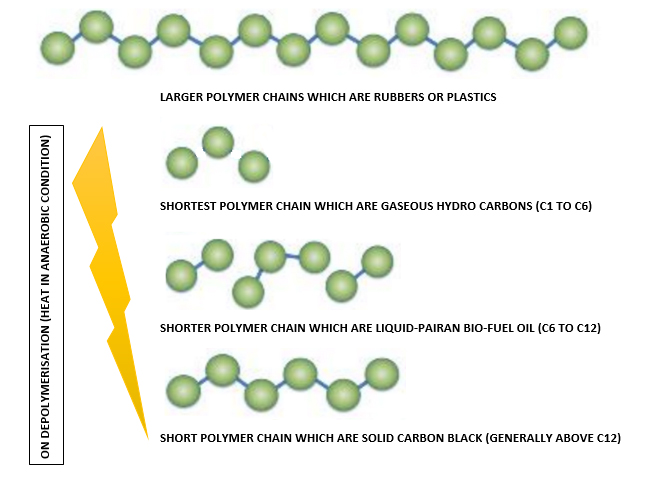

Depolymerization which are is also known as thermal cracking, Reverse cracking, thermolysis etc.. is a chemical reaction involving anaerobic combustion to breakdown longer molecular chains into to more simpler and shorter molecular chains.

Depolymerization which are is also known as thermal cracking, Reverse cracking, thermolysis etc.. is a chemical reaction involving anaerobic combustion to breakdown longer molecular chains into to more simpler and shorter molecular chains.

During depolymerization on specific operating parameters, Plastics and rubber breaks down into smaller molecules of Liquid Bio-Fuel oil, Hydro Carbon gas and solid carbon black. Illustration of same for easy understanding as follows:

This process takes place under the temperatures typically around 350 to 400 C. Products of depolymerization can undergo the following transformations in downstream processes:

- Cooling down followed by oil condensing; liquefaction is applicable for a limited number of feedstock, such as plastics or rubber

- cracking and cleaning in order to be used as fuel in a gas engine to generate electricity

- Further treatment of the depolymerization char to convert into MET coke

ECOLOGICAL ADVANTAGE OF PAIRAN’s TECHNOLOGY

Some of the advantages of depolymerization are that the process is relatively insensitive to its input waste, combustion products associated with the burned solid waste are not generated, and dioxins formation can be efficiently prevented. Pairan’s system demonstrates excellent practical performance in controlling the emission of harmful substances such as dioxins with levels dramatically lower than regulation values.

- The depolymerization facility is self-sustainable, i.e. fuel is required only for start-up operations. Steam and/or electricity generated during operation is further supplied outside of the facility to the customers.

- Another environmental aspect is the reduction of the residuals to be sent for landfill disposal. Some remaining non-toxic carbon char can also be used in the metallurgical industry.

- Produce renewable base load energy thereby reducing greenhouse gases, Creating good-paying, green jobs complementing and enhancing recycling goals and carbon offset targets of the nation